CLINIC range

The concept

CLINIC range has been created to meet the increasingly stringent

requirements in relation to air quality, in sectors such as Dental,

Medical and Food&Beverage industry, as well as in laboratory

applications and in Biogas production processes. These results have been achieved thanks to the combined use

of different technologies:

What can these condensed technologies guarantee within the CLINIC range products?

Who are CLINIC piston compressors

developed for?

Dental clinics

CAD/CAM

Hospitals and medical laboratories

Food laboratories

Chemical, mechanical, electronic laboratories

Biogas production (Nitrogen, etc.)

Wineries

Breweries

Photovoltaic systems

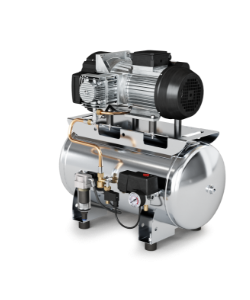

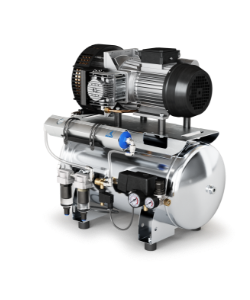

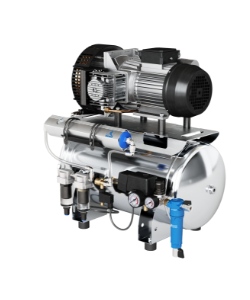

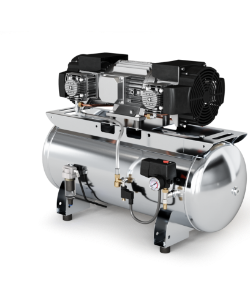

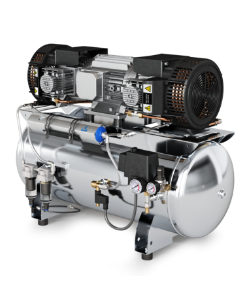

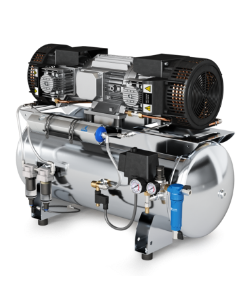

The range

| Power | From 1,8 to 6,0 kW |

|---|---|

| Tanks | From 40 to 500 Lt |

| Air quality | Up to class 0-2-0 (ISO13285) |

| Service class | 100% ON - Continuous duty |

| Max pressure | 10 bar |

| FAD | From 330 to 660 lt/min |

| Maintenance overhaul | 3.000 hr |

| Tank coating | AISI 304 stainless steel |

| Sound level | From Quiet to Ultra-Quiet (55-78 dB) |

Features

Axxer oil-free patented mechanics

- Pure oil-free air (Class 0)

- Non-stop duty 100% ON at 10 bar

- 3,000 hours of work before first maintenance is needed

Stainless steel tanks

- Aseptic and food grade AISI 304

- No risk of corrosion and contamination

Soundproofed pumps

- Great comfort thanks to low noise emissions (down to 67 dB)

S1 class motors

- Non-stop duty 100% ON

- High efficiency low ampere absorption

Hour-meters

- Exact monitoring of workloads

- Precise control of maintenance intervals

Rubber dampers

- Perfect dissipation of vibration for maximum component reliability and durability

- Relevant acoustic insulation

Optimal functionality

- Automatic condensate drain from the tank. Avoids accumulation and contamination due to condensate stagnation

- Solenoid valve for a secure pressure discharge in cases of sudden lack of electricity

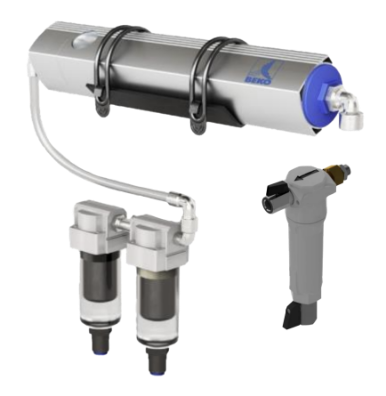

Air Treatment

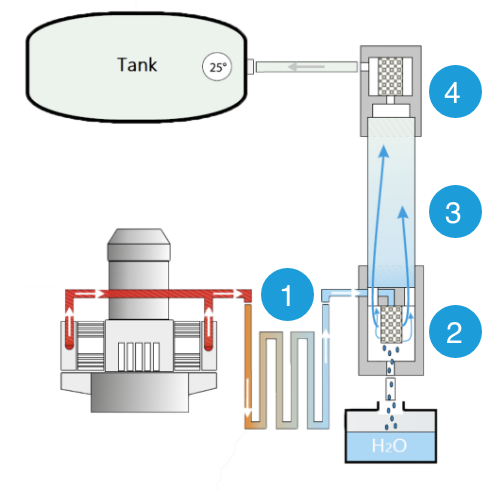

PURE AIR THROUGH 4 STAGES

Compressors of the CLINIC range (DRY versions) are equipped with a 4 stage air drying system, developed by our engineering team to ensure a constant air flow and maximum air purity.

EFFICIENCY AND

DURABILITY

CLINIC range air treatment system (DRY versions) can operate continuously non stop and does not require expensive maintenance or replacement of cartridges or drying substances

MEDICAL GRADE

AIR

The air generated has a degree of purity guaranteed up to class 0 2 0 (ISO 12385 standards) and an output temperature that never exceeds 10 ºC from the ambient temperature

1

st STAGE

Temperature reduction

The heat exchanger reduces the temperature of the air coming out of the pumping unit and facilitate condensate misting, preparing the air flow for the second stage of the process

2

nd STAGE

Air/Water separation

A sequence of two SMC air/water filter separators separates the air from the nebulized condensation and acts as a first barrier to any contaminating particles with a 20 to 0 5 micron molecular sieve

3

rd STAGE

Drying air through membrane fibers

The air flow is guided through the fibers of the world class BEKO membrane dryer unit, until it reaches the dew point of 40 C from the ambient temperature (at the reference pressure of 10 bar)

4

th STAGE

Sterilization (HS models)

During the last stage dry air enters the sterilizing filters ( that acts as a barrier for contaminating molecules by sterilizing the air flow through a 0 01 micron molecular sieve

Advantages for the user

offer the user several advantages:

Ensuring a

healthy

workplace

Avoid downtimes technical issues and delays

Avoid contamination

and

products

decay

Acoustic

comfort in any

situation

Maintenance costs reduced to an absolute minimum

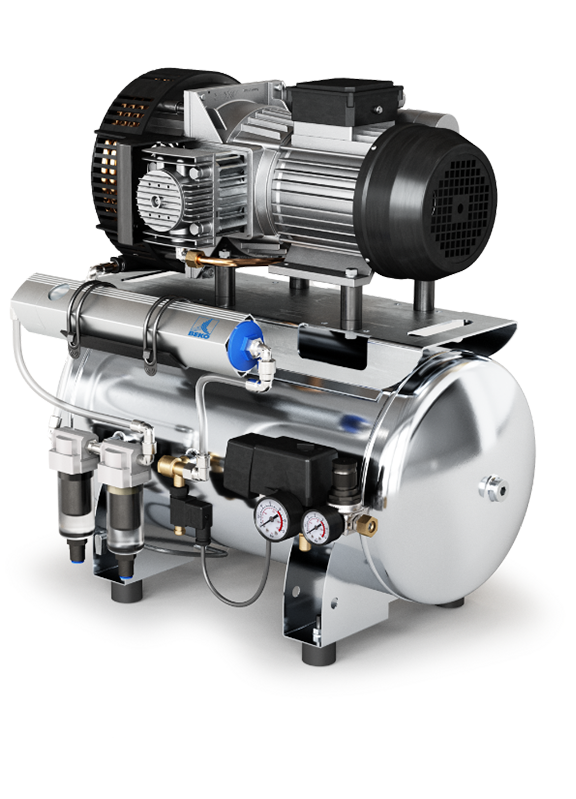

CLINIC Piston Compressors Technical Chart

| CLINIC 3/40 | CLINIC DRY 3/40 H | CLINIC DRY 3/40 HS | CLINIC 6/90 230V | CLINIC 6/90 400V | CLINIC DRY 6/90 H 230V | CLINIC DRY 6/90 H 400V | CLINIC DRY 6/90 HS 230V | CLINIC DRY 6/90 HS 400V | CLINIC 12.500 | CLINIC 12.500 H | CLINIC 12.500 HS | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

| Intake Air | 190 lt/min | 170 lt/min | 170 lt/min | 340 lt/min | 390 lt/min | 320 lt/min | 330 lt/min | 320 lt/min | 330 lt/min | 780 lt/min | 680 lt/min | 680 lt/min |

| Air delivered at 5 bar | 155 lt/min | 135 lt/min | 135 lt/min | 260 lt/min | 310 lt/min | 235 lt/min | 265 lt/min | 235 lt/min | 265 lt/min | 620 lt/min | 530 lt/min | 530 lt/min |

| Max bar | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| dB | 67 dB | 67 dB | 67 dB | 72 dB | 74 dB | 72 dB | 74 dB | 72 dB | 74 dB | 78 dB | 78 dB | 78 dB |

| Tank | 40 lt | 40 lt | 40 lt | 90 lt | 90 lt | 90 lt | 90 lt | 90 lt | 90 lt | 500 lt | 500 lt | 500 lt |

| Dimensions | 65x46 x65 (39kg) |

65x46 x66 (42kg) |

65x46 x66 (42kg) |

99x49 x71 (82kg) |

99x49 x71 (82kg) |

99x49 x71 (86kg) |

99x49 x71 (86kg) |

99x49 x71 (86kg) |

99x49 x71 (86kg) |

204x67 x98 (340kg) |

204x70 x98 (346kg) |

204x70 x98 (348kg) |

| Working cycle | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% | S1 100% |

| Maintenance interval | 3.000 hr | 3.000 hr | 3.000 hr | 3.000 hr | 3.000 hr | 3.000 hr | 3.000 hr | 3.000 hr | 3.000 hr | 3.000 hr | 3.000 hr | 3.000 hr |

* mandatory fields

Do you need more information on Gentilin process air compressors?

We are at your disposal, contact us here