Pro-S range

The concept

GENTILIN’s PRO-S range has been conceived and developed with 5 key concepts in mind:

- No maintenance needs / Minimum operating costs

- Non-stop work in any working environment

- Greater life cycle than commonly traded products

- Minimum footprint / maximum power

- Unparalleled acoustic comfort

These results have been achieved thanks to the combined use of different technologies:

- AXXER patented oil-free mechanics

- Scientific studies on noise generation and propagation

- Aerospace materials and mechanical machining

- S1 class electric motors

a 90% reduced

operating cost

times greater than

traditional compressors

that guarantee total comfort

in your working environment

Who are PRO-S piston compressors

developed for?

01

• Artisans on the road

• Carpenters

• Mobile workshops

• Woodworking

• Plumbers

• Installers

• Construction companies

• Electricians

• Fair stand construction companies

02

• Car reapair shops

• Auto body shops

• Machinery workshops

• Joineries

• Carpentries

• Small industries

03

• Farms

• Wineries

• Breweries

• Food laboratories

• Jewelry laboratories

• Veterinary

• Podology

The range

| Power | From 2,2 to 4,0 kw |

|---|---|

| Tanks | From 3 to 90 Lt |

| Air quality | Oil-free Classe 0 (ISO 13285) |

| Service class | S1 - 100% ON – Continuous duty |

| Max pressure | 10 bar |

| FAD | From 330 to 660 lt/min |

| Maintenance overhaul | 3.000 hr |

| Tank coating | Epoxy coating (internal/external) |

| Sound level | Quiet (68-76 dB) |

| Accessorization | Hour-meter and moisture traps on on 3,0 and 4,0 kw based products |

Features

Extendable handle

- Great comfort during handling

Ultra-compact design

- Vertical deisng and reduced tanks size thanks to the high power and efficiency

- 60% more compact than comparing products

- 50% lighter than comparing products

Industrial grade suction and compression system

- Industrial expanded paper filters stop particulates and dust;

- Stainless steel valve plates resistant to corrosive agents

- 100% guaranteed functionality even in dusty and corrosive environments

Robust chassis

- Shock and drop resistant

- Structure hookups for easy lifting with hoists and cranes

S1 class motors

- Continous duty - no need for cooling stops

- Highest performance and elimination of downtimes when at work

- Automatic thermal protection

PU foam wheels

- Increased size and strenghtened for longer durabilty

- Easy handling on rough terrains

Oil-free patented mechanics

- Zero maintenance up to 3.000 hours of work

- Allowing work and handling in any position (vertical/horizontal)

- Fully smooth functionality below freezing point

- Smooth and problem-free start-ups with low voltage current or with extension cords

Great acoustic comfort

- Silenced motor and mechanics

- Work freely in noise sensitive environments

- Work without personal safety devices for noise protection

Advantages for the user

Easy

transportation

anywhere

• Easy to raise using hoists and cranes thanks to hooks and structural supports

• Place them anywhere with no headhake of dirty surfaces thanks to the absence of lubricating oil

Work in

any environment

and situation

• Optimal operation both in hot environments (+40°C) and below freezing

• Transport and work in both horizontal and vertical positions

100%

operation

without interruptions

• Zero risk of breakage or technical stops due to lack of maintenance or overhaul

Work in a

more comfortable

environment

• Eliminates the need to wear DPM devices for noise

Minimize

rework

and waste

• No problems due to oil nebuization in the atmosphere

• No cleaning costs

Save

space

at work

• Small tanks thanks to high mechanical efficiency

Zero

maintenance

costs

• Zero breaks and stops for lack of care

Tool matching

| CSK330/03 |

CSK330/24 |

CSK330/50 |

CSK330/100 |

ESK480/10 ESK660/10 |

ESK480/100 ESK660/100 |

|

|---|---|---|---|---|---|---|

| Plastering machines | ||||||

| Aerographs HVLP | ||||||

| Aerographs | ||||||

| Small nailers | ||||||

| Medium/Big nailers | ||||||

| Chisels | ||||||

| Orbital sander | ||||||

| Small orbital sanders | ||||||

| Medium orbital sanders | ||||||

| Plasma cutting machines (use combined with dryers) | ||||||

| Impact wrenches | ||||||

| Pneumatic cutters |

Machinery Matching

| CSK330/03 |

CSK330/24 |

CSK330/50 |

CSK330/100 |

ESK480/10 ESK660/10 |

ESK480/100 ESK660/100 |

|

|---|---|---|---|---|---|---|

| Nytrogen generators (please use dryers) | ||||||

| Milking rooms | ||||||

| Grape pressing systems | ||||||

| Bottling machines | ||||||

| Water depuration systems | ||||||

| Beverage dispensing systems | ||||||

| Painting workshops systems | ||||||

| Machinery for veterinary | ||||||

| Poldology equipments |

They can do the same job!

Mod. CSK330/24

3 Hp 24 Lt. 36 Kg - 67 dB

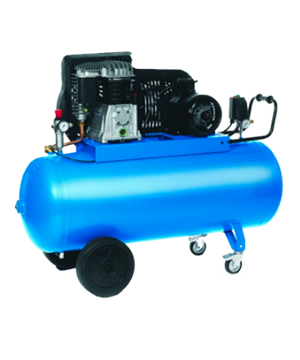

Traditional compressor

3 Hp 100Lt. 67 Kg- 90 dB

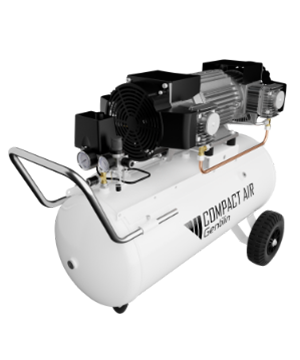

Mod. ESK660/100

5,5 Hp 100Lt. 64Kg - 67dB

Traditional compressor

5,5 Hp 270 Lt. 170 Kg - 97 dB

PRO-S Piston Compressors Technical Chart

| CSK300/03 | CSK330/24 | CSK330/50 | CSK330/100 | ESK480/100 | ESK480/100 | ESK660/100 | ESK480/10 | ESK660/10 | |

|---|---|---|---|---|---|---|---|---|---|

| Type |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

| Voltage/Hertz | 230V - 50Hz | 230V - 50Hz | 230V - 50Hz | 230/400V - 50Hz | 230V - 50Hz | 400V - 50Hz | 400V - 50Hz | 230V - 50Hz | 230V - 50Hz |

| FAD | 330 lt/min | 330 lt/min | 330 lt/min | 330 lt/min | 230 lt/min | 480 lt/min | 660 lt/min | 430 lt/min | 660 lt/min |

| Air delivered at 5 bar | 200 lt/min | 200 lt/min | 200 lt/min | 200 lt/min | 260 lt/min | 310 lt/min | 400 lt/min | 260 lt/min | 400 lt/min |

| Max bar | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| dB | 68 dB | 68 dB | 68 dB | 68 dB | 72 dB | 74 dB | 76 dB | 72 dB | 76 dB |

| Tank | 3 lt | 24 lt | 50 lt | 90 lt | 90 lt | 90 lt | 90 lt | 10 lt | 10 lt |

| Dimensions |

47x40x60cm (32kg) |

55x48x79cm (36kg) |

55x48x103cm (44kg) |

101x53x71cm (56kg) |

103x53x73cm (76kg) |

103x53x73cm (76kg) |

103x53x73cm (76kg) |

79x58x57cm (50kg) |

79x58x57cm (50kg) |

| Working cycle | 100 % | 100 % | 100 % | 100 % | 100 % | 100 % | 100 % | 100 % | 100 % |

| Maintenance interval | 3.000 hr | 3.000 hr | 3.000 hr | 3.000 hr | 3.000 hr | 3.000 hr | 3.000 hr | 3.000 hr | 3.000 hr |