Smart series

The concept

GENTILIN SMART range was born from the need to provide silent products equipped with air treatment systems to meet the common needs of different sectors, including: dental, podiatry, veterinary, food&beverage. The strengths of the SMART range are the following:

- “Class 0” oil-free air;

- Dry Air, with dew point down to -20°C;

- Quiet operation;

- Simplified functionality and maximum reliability.

These results were achieved thanks to the combined use of different technologies:

- Oil-free mechanics;

- Silenced air intake valves;

- Tanks treated internally with epoxy coating;

- Adsorption dryers.

What advantages do the integrated technologies in the SMART product line offer?

Who are SMART piston compressors

developed for?

Dental clinics

Podology

Veterinary

Hospitals and medical laborotires

Food&Beverage workshops

Clean-rooms

Wine making processes

Beer making processes

Industrial printing

Pakcaging processes

Food&Beverage workshops

The range

| Power | From 0,75 to 3,0 Kw |

|---|---|

| Tanks size | From 24 to 90 Lt |

| Air quality | Oil-free «class 0» and dryeddown to -20°C dewpoint |

| Service class | S3 - 70% ON |

| Max pressure | 8 bar |

| FAD | From 150 to 440 lt/min. |

| Maintenanceoverhaul | 1.500 hr |

| Tanks material/treatment | Stellwith externaland internal expoxy coating |

| Sound level | Ultra-quiet (55-68 dB) |

Functionalities

Smooth operation

- Automatic condensate drain from the tank. Avoid accumulations and contamination due to condensation stagnation (optional).

- Solenoid valve for pressure relief activate in case of sudden lack of electricity, protecting the motor and the pressure circuit.

Epoxy coated tanks

- Internal/external epoxy painting.

- No risk of corrosion and contamination.

Quiet pumps

- Maximum comfort thanks to reduced noise emissions (down to 55 dB).

Anti-vibration pads

- Reduce redundancy for maximum reliability and durability of components over time.

- Noise reduction.

Oil-free sturdy mechanics

- Oil-free class 0 air.

- 8 bar smooth operation.

- First maintenance after 1.500 hours of work.

S3 class 70% ON motors

- Smoothheavy duty work up to 45 minutes per hour.

- High efficiency, low consumption.

Air Treatment

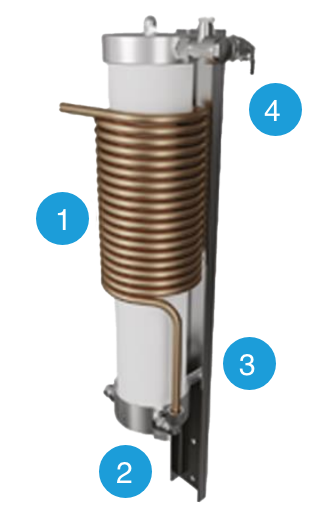

PURE AIR IN 4 STAGES

Compressors of the SMART range (DRY versions) are equipped with a 4-stage air drying system, chosen by our engineers to guarantee a constant air flow of maximum purity.

EFFICIENCY AND

FUNCTIONALITY

The silica gel drying system developed for the SMART range (DRY versions) can work on an intensive cycle (Up 70% ON)

AIR QUALITY

The air generated has a guaranteed degree of purity up to class 4-3-0 (ISO12385 standard) and an outlet temperature that never exceeds + 10°C from the ambient temperature

STAGE 1

Air temperature reduction

The heat exchanger reduces the temperature of the air exiting the compressor unit and favors the atomization of the condensate, preparing the air flow for the second stage of the process

STAGE 2

Air/Condensate Separation

Thanks to its composition, the cyclonic air/water separator separates the majority of the condensation form the air and channels it towards the lower part of the dryer.

STAGE 3

Drying through silica gel

The airflow is guided through the silica gels on the dryer internal chamber. Through this stage the air reaches a dew point of -20°C from the ambient temperature (At the reference pressure of 8 bar).

STAGE 4

Rigeneration

During the downtime (pauses) of the compressor, the desiccant gel is regenerated by a returning air flow that comes from a second outer chamber of the dryer, guaranteeing long life and minimal maintenance.

Advantages for the users

offer numerous advantages for the end-users:

Ensure a

healty

workplace

Avoid delays and technical stops in your business

Avoid contamination and deterioration of products

Great acoustic comfort in any situation

Maintenance costs reduced to a minimum

SMART Piston Compressors Technical Chart

| SMART 1.10 |

SMART 1.25 |

SMART DRY 1.25 | SMART 2.25 |

SMART DRY 2.25 | SMART 2.50 | SMART DRY 2.50 | SMART 4.90 | SMART DRY 4.90 | SMART 1.25-S | SMART DRY 1.25-S | SMART 3.25-S | SMART DRY 3.25-S | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

Oil-free (intensive use) |

| FAD | 105 lt/min | 105 lt/min | 105 lt/min | 170 lt/min | 170 lt/min | 170 lt/min | 170 lt/min | 330 lt/min | 330 lt/min | 95 lt/min | 95 lt/min | 200 lt/min | 200 lt/min |

| Air delivered at 5 bar | 75 lt/min | 85 lt/min | 85 lt/min | 140 lt/min | 140 lt/min | 140 lt/min | 140 lt/min | 280 lt/min | 280 lt/min | 72 lt/min | 72 lt/min | 155 lt/min | 155 lt/min |

| Max bar | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 10 | 10 |

| dB | 60 dB | 60 dB | 60 dB | 65 dB | 65 dB | 65 dB | 65 dB | 68 dB | 68 dB | 62 dB | 62 dB | 67 dB | 67 dB |

| Tank | 10 lt | 24 lt | 24 lt | 24 lt | 24 lt | 50 lt | 50 lt | 90 lt | 90 lt | 24 lt | 24 lt | 24 lt | 24 lt |

| Dimensions | 120x80 x180 (490kg) |

114x68 x190 (176kg) |

114x68 x190 (208kg) |

114x68 x190 (200kg) |

114x68 x190 (228kg) |

42x40 x86 (48kg) |

55x40 x86 (55kg) |

99x39 x76 (67kg) |

99x53 x83 (86kg) |

42x42 x70 (31kg) |

46x42 x81 (39kg) |

42x42 x74 (40kg) |

57x68 x95 (45kg) |

| Working cycle | S3 70% | S3 70% | S3 70% | S3 70% | S3 70% | S3 70% | S3 70% | S3 70% | S3 70% | S3 70% | S3 70% | S3 70% | S3 70% |

| Maintenance interval | 1.500 hr | 1.500 hr | 1.500 hr | 1.500 hr | 1.500 hr | 1.500 hr | 1.500 hr | 1.500 hr | 1.500 hr | 1.500 hr | 1.500 hr | 1.500 hr | 1.500 hr |

* mandatory fields

Do you need more information on Gentilin process air compressors?

We are at your disposal, contact us here